In today’s post we share our findings on how much IPA can impact warping during post cure of SLA resin 3D prints and why it’s critical to dry parts more thoroughly than you think.

Read MoreWe’ve been running an extremely low cost, easy to use DIY heated chamber setup on our Bambulab X1C for around a year now with great success. The amount of warping on ABS, PC, and Nylon parts can be dramatically reduced by using a heated chamber.

Read MoreWatch our presentation on post processing, presented at the 2024 Formlabs User Summit!

Learn some useful tips & tricks to make post-processing suck less.

Read MoreIn the past we struggled with some build plates failing on Formlabs machines. The covers on the sides would pop out and no matter what you did they would continue to do so.

One of the things I love about engineering is being able to solve problems using First Principles. If we take apart a build plate and ask ourselves why this happens, we can come up with an explanation and solution.

Read MoreIn today’s post we want to share our findings on how flexible and elastic resins require significantly longer drying times than rigid resins in order to preserve dimensional accuracy.

Read MoreIn this blog we show how to build a cheap DIY fume hood in order to keep fumes from 3D printing at bay. This helps contain and filter VOCs and particulates generated with resin 3D printing and/or filament 3D printing.

Read MoreOver the past three months we’ve been printing production parts for a local medical device company as a stop gap until they got their injection mold tooling up and running. It’s pretty amazing to think that one can now rapidly scale up and do production using 3D printing in situations like this.

Read MoreFor the past three months we’ve been working on a new product. Funnily enough this wasn’t on our roadmap and was kind of an “accident” - but the amount of interest and traction led us to refine and release this next product.

For the first time ever, you can add your own logo and flair to a high quality, double sided, textured PEI plate or add your own pattern that will transfer onto parts.

Read MoreWe’ve been printing with Formlabs machines for many years now - starting from the Form 2, and now to the Form 3, Form 3B and Form 3L. These machines have been an integral part of our business and have allowed us to help hundreds of customers with their product development.

Knowing this, it’s no surprise that we have developed very specific processes internally in order to keep a tidy, clean and efficient workspace. In this post I want to share how we’ve been effortlessly removing parts from build plates. This is based on years of experience across every possible resin type, over thousands and thousands of parts.

Read MoreIt’s been around a year since we’ve launched our first product - the Camera Assisted XY Calibration Tool (or CXC for short). This is an optical tool which makes XY offset calibration on multi-extruder printers much easier, faster, and more accurate. Gone are the days of having to print annoying line patterns. In fact, our hate for the traditional line patterns is exactly why we developed the CXC for our Raise3D E2 before we brought it to life as a product for others.

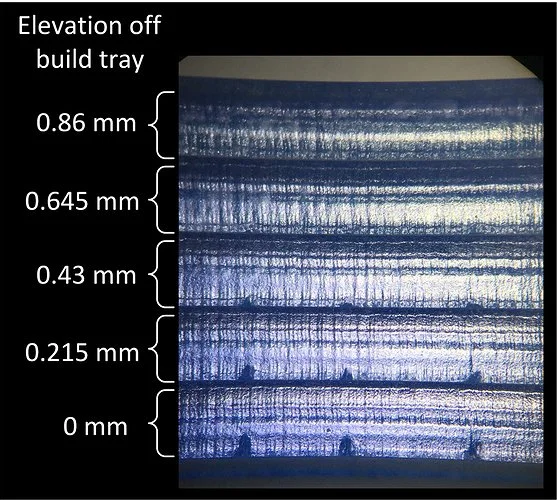

Read MoreLaser cutting sometimes induces artifacts on the bottom of your material due to reflection of the laser off the bed surface and back into the workpiece. This phenomenon is known colloquially as “flashback”.

While flashback isn’t a big deal during prototyping, it can be noticeable on production parts, or any part that needs to look more polished. It’s especially visible when laser cutting thicker clear acrylic.

However, there are simple ways to solve this. As seen below, flashback can be reduced or eliminated by elevating your workpiece above the work table.

Read MoreVacuum forming is traditionally a slower manufacturing process. Typically a mold needs to be machined, which requires programming & setup time, and then the thermoplastic gets formed. With 3D printing, one can print a mold overnight and form the parts the next day.

Vacuum forming can be done both with FDM and SLA. The latter yields much higher quality in terms of surface finish but is more costly to produce, especially when molds are larger in size. In this blog post we highlight two examples, one with an FDM printed mold, and one with an SLA printed mold.

Read MoreThere’s lots of talk these days about printing tooling for short run injection molding, or printing rigid molds for silicone casting.

One unique application is low volume, flexible 3D printed molds for rigid overmolding of electronics.

In this blog post we’ll cover how we used SLA 3D printing to make flexible molds that allowed us to overmold electronics for a polar bear tracker. This was a project done in collaboration with Mistywest and you can read about the project specifics here.

Read MoreOne of our thoughts and conclusions from the research was that flow plays a large factor in part strength and part defects resulting from high speed printing. This was confirmed empirically by Stefan (CNC Kitchen) in the video linked above. Flow can be affected by many factors, and one of them is filament. This is what we want to discuss today. Specifically - “flowability” of filament, also known as Melt Flow Index (MFI).

Read MoreSince the release of the Bambu Lab X1, there’s been a lot of discussion around high speed printing. Two common things we hear are 1) high speed printing results in poorer mechanical properties and 2) high speed printing results in poorer accuracy. As engineers, we wanted to do some research to see if these statements are really true. This blog post covers some of the research and findings that we’ve seen.

Read MoreThis is a follow-up to our previous post about water soluble supports. After significantly more testing of various brands of filament and material types - we’ve converged on using Stratasys SR30.

While this requires purchasing Ecoworks tablets, this is the absolute best support material to use across a wide variety of engineering materials hands-down.

Read MoreDid you know that you can create chamfers and even countersink holes with a laser cutter? While it may not seem like a big deal to do this with a drill or drill press for one-offs, this could be a very useful trick for reducing labor on low volume production parts - such as a batch of locally hand made goods.

Read MoreMore and more jigs and fixtures in the manufacturing and assembly space are being 3D printed. With this comes challenges in preventing static build up from damaging sensitive electronics, especially when assembling devices like lasers.

Thankfully there are an increasing number of ESD safe materials that are available. The first step to choosing the right material is understanding what Anti-Static, Static Dissipative and Conductive means.

Read MoreAt Ember we try to minimize our carbon footprint as much as possible. Being a part of the 3D printing industry, we’re adding a significant amount of plastic waste into the ecosystem. Couple that with solvent waste and that makes things twice as bad for the environment.

Many people in the industry don’t talk about the “dark side” of 3D printing. This typically revolves around solvent waste, and post-processing labour. In the former, at least here in British Columbia, solvent waste cannot be easily recycled. In fact, we have paid chemical companies in the past to take our solvent waste, only to discover that they dispose of it by incineration.

Read MoreJust because a printer’s build volume is smaller than your designed object doesn’t mean you can’t 3D print it. Here at Ember, we’ve made lots of very large parts that were broken up into several pieces and then bonded together. There are caveats of course - your part can have weak spots along the bonding regions, the surface finish on the bonding area can look slightly different, and it requires some manual labor.

Read More