Eliminate Laser Cutting Flashback

Laser cutting can induce artifacts on the bottom of your material due to reflection of the laser off the bed surface and back into the workpiece. This phenomenon is known colloquially as “flashback”.

While flashback isn’t a big deal during prototyping, it can be noticeable on production parts or any part that needs to look more polished. It’s especially visible when laser cutting thicker clear acrylic.

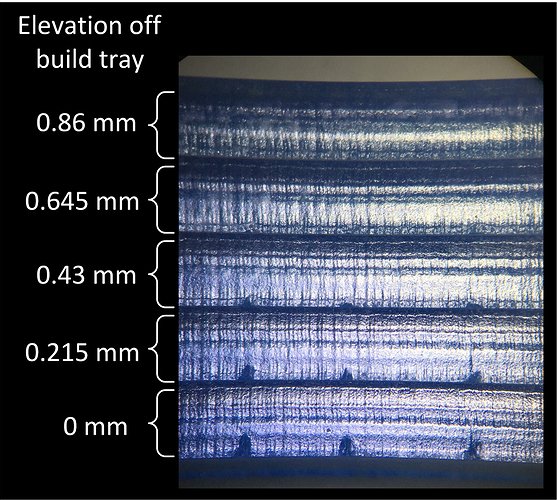

However, there are simple ways to solve this. As seen below, flashback can be reduced or eliminated by elevating your workpiece above the work table.

Flashback

This image (taken from a Glowforge forum post) illustrates how flashback can be eliminated by simply elevating the workpiece off the table surface.

In order to eliminate or mitigate flashback, we use a technique borrowed from laser cutting leaders Trotec. Trotec’s trick is to laser cut acrylic blocks that space the workpiece up from the table.

Some individuals use tall “pin tables” to achieve a similar result. However, it’s important that the workpiece isn’t spaced so high up that parts fall and bounce around on the bottom of the work table. If cut parts bounce over to an area yet to be cut, it will get scarred by any residual laser energy piercing through the next location, ruining the part. Trotec’s solution is convenient because it’s modular and so placement and number of blocks can be tweaked for the specific job and material. It’s also entirely consumable and you can simply cut more pieces when needed.

For those who own a laser cutter, or are familiar with flashback, this is a great, quick, and modular tool for eliminating it. You can download our DXF here so you can cut this yourself. For our honeycomb table, cutting this out of 1/4’’ acrylic works great - we hope this helps you out!

Pin Tables

These achieve the same result but with some disadvantages. the metal pins can still reflect and smaller pieces can fall then be hit with the laser. Acrylic blocks are much cheaper, easier to work with, easy to replace, and are modular.