Camera Assisted XY Calibration - Our First Product

It’s been around a year since we’ve launched our first product - the Camera Assisted XY Calibration Tool (or CXC for short). This is an optical tool which makes XY offset calibration on multi-extruder printers much easier, faster, and more accurate. Gone are the days of having to print annoying line patterns. In fact, our hate for the traditional line patterns is exactly why we developed the CXC for our Raise3D E2 before we brought it to life as a product for others.

Now we’ve helped hundreds of people with their calibration, as well as partnered with several OEM manufacturers and resellers. It’s definitely been rewarding to see the adoption of the CXC take place across many different printer types and brands.

XY Offsets

An example of the traditional method of calibrating with line patterns. A subjective, inaccurate, and time consuming process.

The CXC is a fairly simple device. It utilizes a camera with a very short focal length lens to capture a video of the nozzle. A piece of Windows software or cross-platform web app is then used to help perform the calibration. The user is required to move the nozzle until it aligns to the center of a cross hair. Absolute positions are recorded, and repeated for the remaining extruders. Once this is complete, the software performs some basic math to calculate offsets for the user which get entered into the machine.

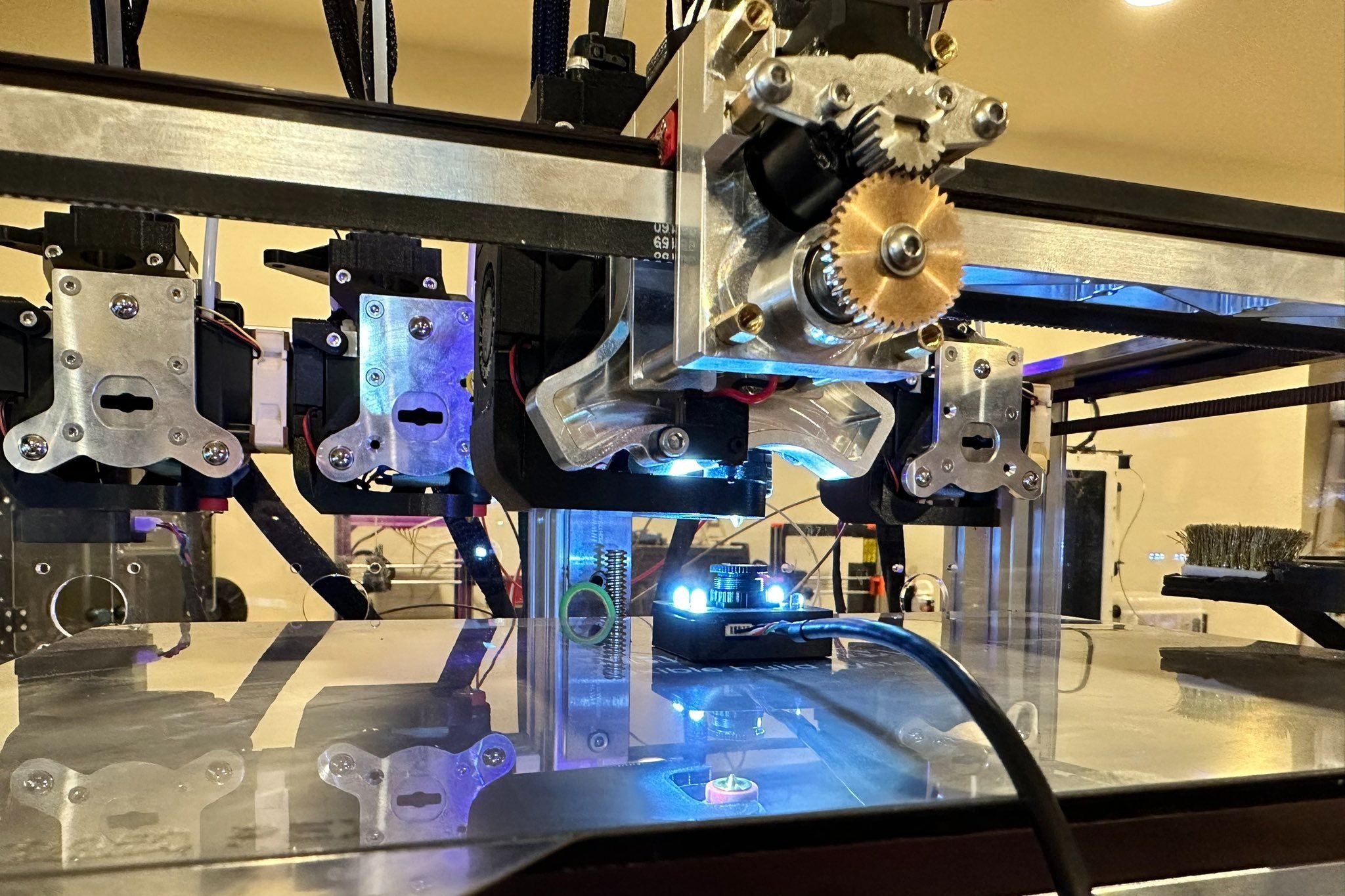

The benefit of this camera-assisted manual calibration is that it’s printer agnostic and can work with any printer or firmware as long as the user can manually move the machine in <=0.1mm steps and override offset values. We’ve had our CXC used on printers such as the Sovol SV04, Prusa XL, E3D Toolchanger, Proforge 4 Toolchanger, Voron StealthChanger & TapChanger, and many others.

Toolchangers

As you start to scale the number of extruders on a 3D printer, the benefit of the CXC also scales. There’s been significant adoption of the cxc across tool changing systems like the e3d toolchanger (now discontinued) and the makertech3d proforge 4 (whom we partnered with during their kickstarter campaign)

If you want to see some more in depth instructions or videos for how the CXC works - check our our product page or watch the videos below.