Effect of IPA on flexible resin print accuracy

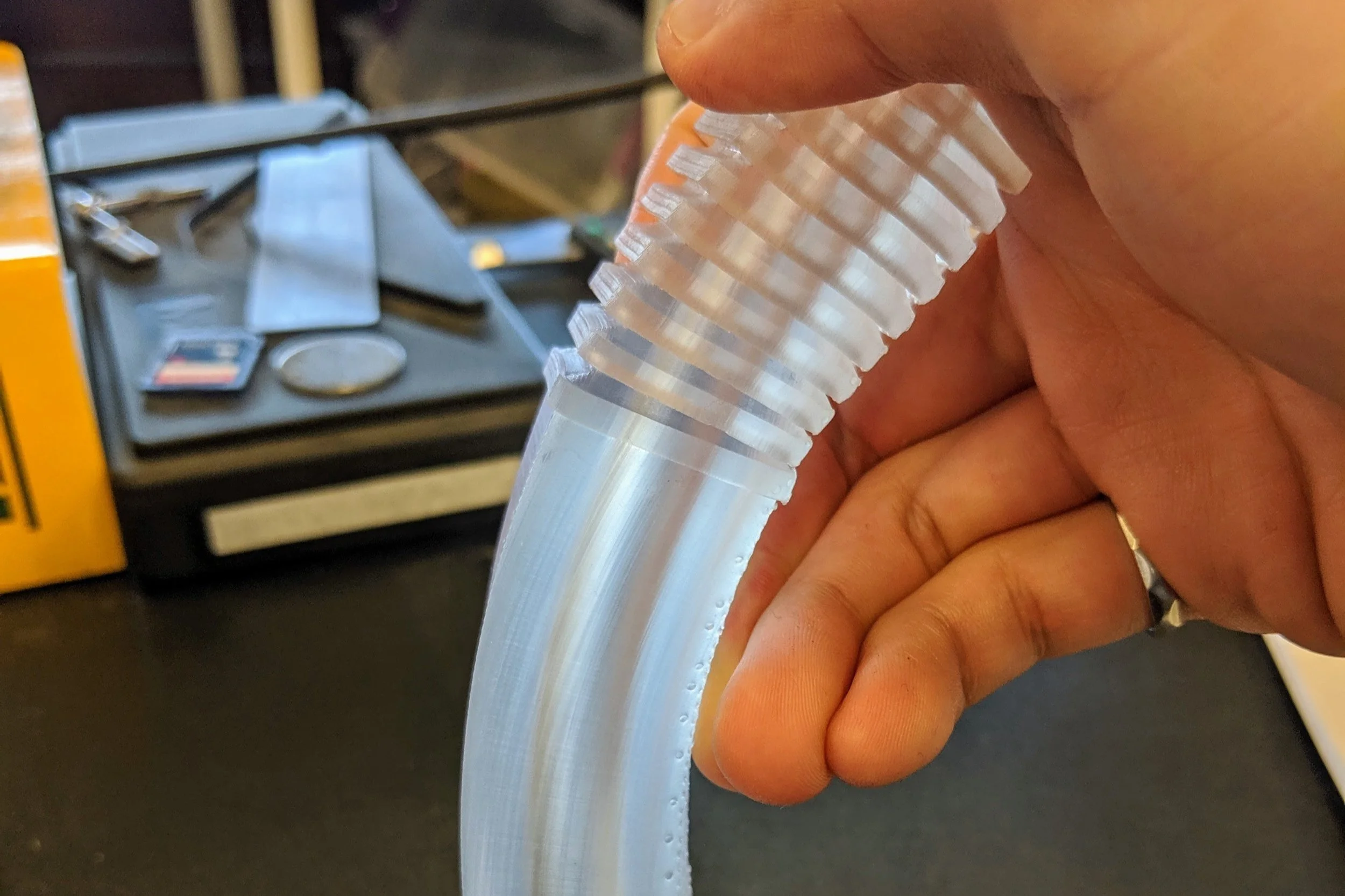

Flexible resins are an amazing way to rapidly prototype soft, rubber-like gaskets and parts. It also allows one to create very unique geometry like squishy heart models that would otherwise be very labor intensive to create (eg. silicone molding or dip/spin casting).

Almost all SLA/DLP resins require washing excess resin in Isopropyl Alcohol (IPA). Similarly, almost all of these resins tend to absorb IPA to varying degrees. Once parts are out of the wash, they need adequate time to dry to prevent fogging and damage of the UV post curing oven. Drying also allows absorbed IPA to evaporate and reduce swelling. If unchecked, absorbed IPA can cause dimensional inaccuracy and warping during post cure.

Our standard process is to let parts dry for at least 12-24 hours. This results in better accuracy, but most importantly, less warp during the heated UV post cure. This last step is the most prone to dimensional warping because the temperatures suggested during post cure by Formlabs are often near the heat deflection temperature (HDT) of the material. There are other tricks to eliminate warping all together, but that isn’t the focus of this post.

Flexible is cool

Being able to 3D print flexible materials is an amazing capability, especially if you design gaskets, flexures, or anything else that needs to repeatedly bend without breaking or deformation. While these materials aren’t as tear resistant as real silicone, they are close.

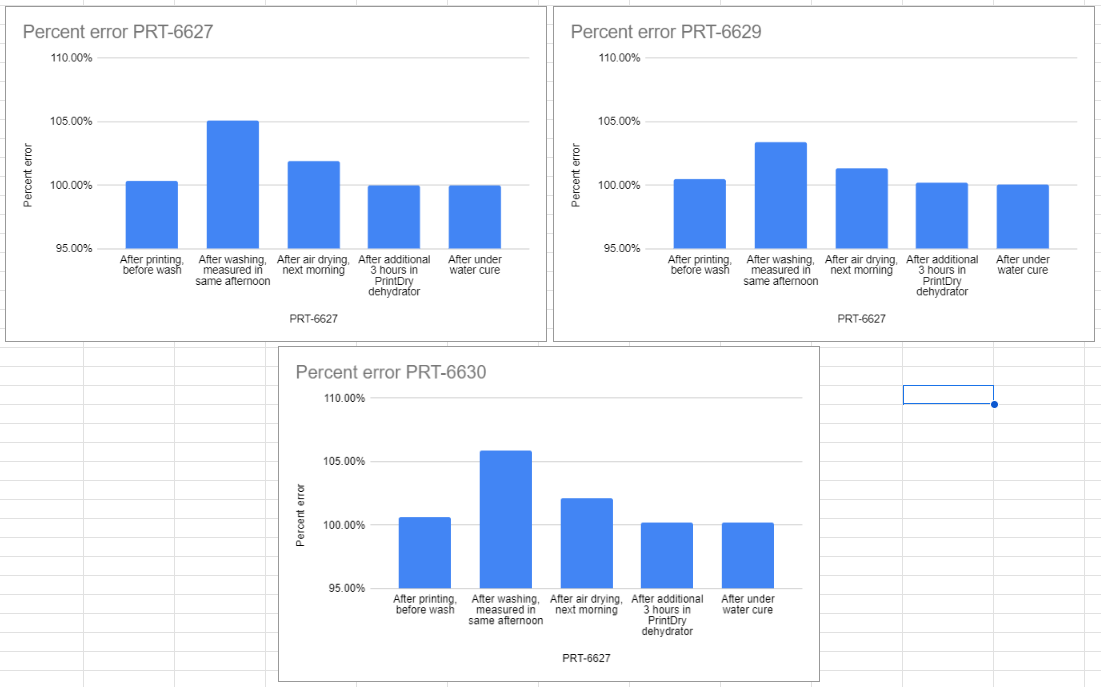

In today’s post we want to share our findings on how flexible and elastic resins require significantly longer drying times than rigid resins in order to preserve dimensional accuracy. We’ve encountered times when parts would routinely be oversized by varying degrees (around 5%) even when following the standard wash times spec’ed by Formlabs. The dimensional inaccuracy got worse the larger the part was printed in the X and Y orientation. This was really frustrating because gaskets printed flat would often not fit their mating grooves.

Poor accuracy

This gasket, printed in elastic 50A, was washed and cured under standard operating conditions. the nominal dimension is supposed to be 50mm, but you can see that it’s measuring at 52mm.

After substantial testing, we’ve found that drying time was the main problem. Even drying small parts for 24 hours is not enough to achieve good tolerances. Here we illustrate that drying times in excess of 24 hours (or accelerated drying using a food dehydrator) can improve accuracy. There are many types of filament dryers and dehydrators out there - below are some examples (affiliate links):

- PrintDry Filament Dryer

- FixDry Filament Dryer

- Sunlu Filament Dryer

- Generic Food Dehydrator

Shown below are graphs plotted from dimensional data that we took during testing and troubleshooting of three different Elastic parts. The graphs clearly illustrate how accuracy is a function of drying time. You can see that dimensional accuracy straight out of the printer is very good, but shoots up after washing in IPA. After 24 hours you can see that the error has decreased, but it’s still not back to it’s original state. An additional 3 hours in a food dehydrator returns the parts to their original dimensions. We suspect that simply running parts in a food dehydrator for 3-6 hours before curing is enough to return parts to their original accuracy.

Unfortunately this isn’t a well known phenomenon so we hope this helps the few others out there who print with super cool but challenging materials like Flexible and Elastic resins.