Water Soluble Supports - PART TWO

This is a follow-up to our previous post about soluble supports. After significantly more testing of various brands of filament and material types - we’ve converged on using Stratasys SR30. While this requires purchasing Ecoworks tablets, this is the absolute best support material to use across a wide variety of engineering materials hands-down.

What we’ve found with other water soluble support materials are either a) adhesion to amorphous polymers suffers (eg. ABS, Polycarbonate) and/or b) solubility is really poor even with high temperature and circulating. Some examples of water soluble supports we’ve tested:

While BVOH does work fairly well with some tricks (as mentioned in the last blog), it doesn’t adhere well enough to some amorphous polymers like PC-ABS or PC, especially on large, dense parts. We found that Aquatek X1 adhered well, but would not dissolve and would turn to a gooey mess. Aquasys 120 & 180 was an underperformer all-around. This material was very difficult to extrude as it seemed to have high viscosity and did not have any significant adhesion improvement over BVOH.

To be frank, it’s quite surprising how little proof some of these companies have when claiming “high adhesion” and “compatibility” to engineering materials. The world of FDM filaments is somewhat of a wild wild west - with many different additives in materials and a lack of accountability for data. Some filament suppliers don’t even provide adequate datasheets for their materials!

Poor Adhesion

Insufficient adhesion can show itself in several different ways. Typically when printing large, thick parts, the support material won’t have enough adhesion to keep the part from warping.

SEcondly, insufficient adhesion strength will cause very small support structures to fall off mid print, contributing to print failures.

Stratasys’ SR30, which is a proprietary material, works amazingly well across any filament we threw at it. This includes ABS, PC-ABS, PC, Nylon, CF Nylon, ESD ABS, etc. Adhesion strength is very strong, but still allows breakaway of the majority of supports with some effort. It can also be bought in smaller spools from Makerbot and prints just like ABS.

Stratasys sells a specific wash station for this material called the SCA-1200. We’ve had the fortune of working with this wash station in the past, and there are low cost older versions circulating on eBay. However, if you’re smart about your material selection, you can get away with creating your own washing station for a fraction of the cost, with similar performance.

If you do attempt this - just make sure all the parts contacting the Ecoworks solution are either Polycarbonate, or Stainless Steel. Ecoworks is a basic hydrogen peroxide solution and Polycarbonate has great chemical compatibility with hydrogen peroxide. We hope you found this interesting, and we’re glad we’ve finally concluded our long search of the “perfect” soluble support material!

Sous vide to the rescue

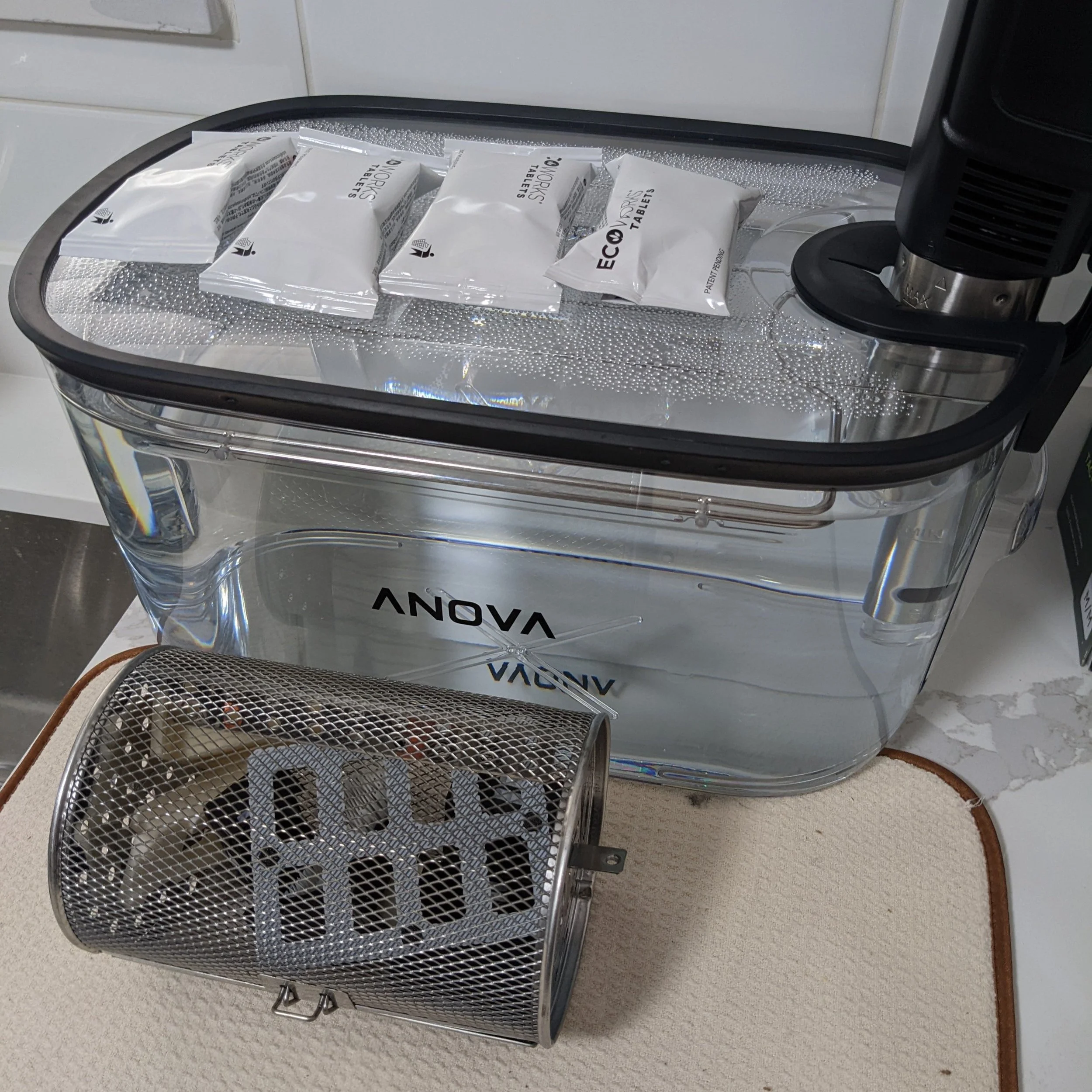

The easiest way to create your own wash station is to use a sous vide kit. this is an anova sous vide wash bucket along with an INkbird sous vide.

There is also a small stainless steel parts basket which was originally intended for barbeques.

This DIY station works extremely well and is a fraction of the cost of the SCA-1200. It also takes up significantly less space.

The only thing that could be improved is the circulation, which can be upgraded by using one or two magnetic stirrers at the bottom of the tank - something we might add in the future.

Dissolved parts

A bunch of dissolved parts out of the wash station & small parts basket.

THis is a collection of ABS, PC-ABS, PC, and Nylon.